Proven Expertise in Anaerobic Digestion Project Delivery

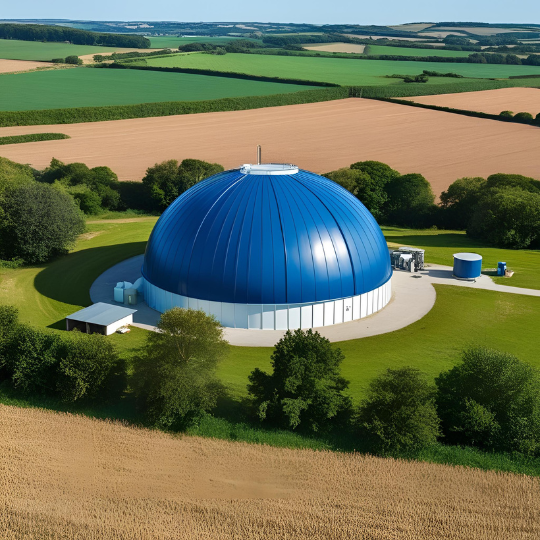

At Paul Winter Consulting Ltd (PWCL), we bring deep technical understanding and hands-on experience to the delivery of anaerobic digestion (AD) facilities. Our team has managed the construction and commissioning of AD plants across the UK, working with developers, operators, and funders to deliver critical infrastructure with long-term value.

From agricultural and food waste systems to larger-scale industrial plants, our expertise spans multiple feedstocks and technologies. We understand the importance of aligning process design with feedstock availability, output requirements, and environmental constraints.

echnical Input from Feasibility Through Planning

Robust early-stage input is critical to the success of AD projects. We work closely with clients during feasibility and planning to define a clear and technically-sound development strategy, aligned with commercial outcomes.

Our team undertakes site assessments, feedstock analysis, grid and utility reviews, and capacity modelling. We help clients understand the viability of different technologies and system configurations, considering CAPEX, OPEX, biogas yields, digestate handling, and compliance requirements.

We support planning and permitting processes by coordinating environmental assessments, preparing supporting technical documentation, and liaising with regulators. Our familiarity with permitting pathways helps accelerate approvals while maintaining environmental and planning compliance.

Managing Procurement, Construction & Risk

PWCL provides detailed procurement support, developing technical specifications and managing tender processes for digester systems, CHP or biogas upgrading, reception areas, storage, and infrastructure. We assess supply chain capability and negotiate robust contract terms to safeguard delivery.

During construction, we manage the day-to-day interface between contractors, designers, and the client. We coordinate site logistics, oversee civil and mechanical works, and ensure quality assurance across all trades.

We have experience with modular and on-site builds, including below-ground tanks, in-situ poured digesters, and prefabricated systems. We closely monitor progress, budget, and compliance—ensuring timely interventions to avoid delays or cost escalation.

Commissioning, Compliance & Operational Readiness

Commissioning an AD plant requires careful coordination and technical oversight. PWCL manages the commissioning process to ensure systems integrate properly, regulatory tests are met, and operational safety is achieved before handover.

We lead performance testing, coordinate with equipment suppliers and specialist commissioning engineers, and manage snagging and documentation close-out. Our team ensures that all compliance checks, safety protocols, and data logging systems are in place.

Operator training is integrated into the final phase, enabling a confident transition to live operations. We also provide support post-handover as needed, including performance monitoring or troubleshooting.