Project Overview

What We Did

Renewable Energy Project

A versatile and efficient approach to waste treatment

PWCL provided various pre-construction and project management-related services for Melton Energy Tech Ltd.’s £25 million dry anaerobic digestion plant in the UK, supporting the project from feasibility through to commissioning and handover.

Project Background

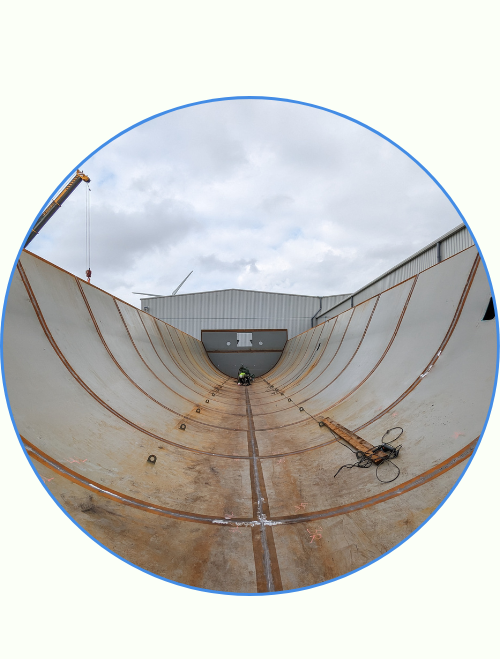

PWCL was appointed by Melton Energy Tech Ltd. to provide pre-construction and project management-related services for the development of a £25 million dry anaerobic digestion (AD) facility in Melton, UK. Unlike traditional “wet” AD, the dry process can handle feedstock with a higher dry matter content of 20–40%, providing an alternative solution for managing organic waste streams.

What we did

Our role included procurement assistance and contract management, coordination and oversight with key partners and contractors, and management of construction and commissioning activities; by aligning technical expertise with real-world knowledge and experience, we ensured the project progressed smoothly and achieved its milestones.

The project required collaboration with several specialist partners such as Thöni who provided the dry AD technology, Wartsila who completed the upgrading system, Thyson Technologies Ltd the grid entry unit and export pipeline, Carbon Electric providing essential M&E expertise and BioDrive completing the balance of plant across the project ensuring all systems and technologies integrated successfully. PWCL is supporting both the technical commissioning and the final handover to operations process.

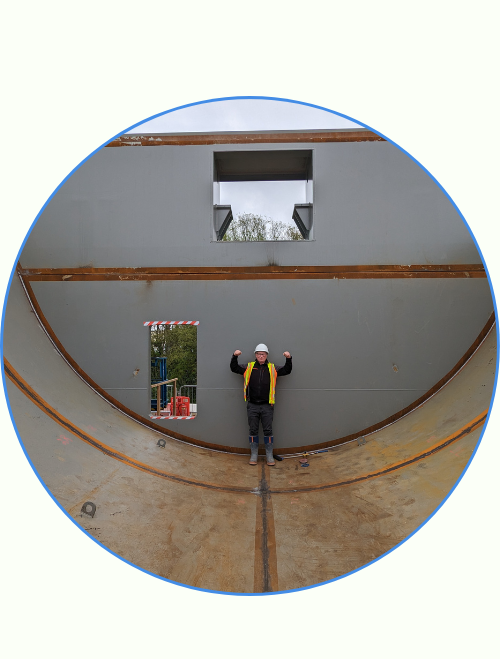

The plant is now in commissioning, marking a significant achievement for both PWCL and Melton Energy Tech Ltd. This project demonstrates PWCL’s capability to deliver complex renewable energy facilities that integrate cutting-edge technology with robust project management. The facility is now positioned to make a meaningful contribution to the UK’s renewable gas capacity.